Q: We’re worried about the offset drainage; how do I bring that into our Drilling Spacing Unit (DSU) analysis?

A: The ultimate effect of parent wells on infill child wells is hard for companies to examine because they lack a direct way of figuring out what that spacing needs to be. “What companies do,” Kyle LaMotta, VP of Analytics at Petro.ai, describes the difficulty, “is look at other wells that have been drilled. They’ll try to find wells in the area that are 500 feet away from parents and ask what’s their average performance. Then they’ll ask what’s the average performance of wells that are 700 feet away from the parent well. They don’t have a way to predict that drainage without running a frac simulator. You can’t run a frac simulator on all the wells because it takes too long.

“Petro.ai has approached this need for information in a direct way. We use predictors that are able to quickly generate all of these different distance scenarios, calculate the drainage, and then use that updated drainage calculation in the model that we create of the reservoir as one of the variables.

“Let me give you an example of building the offset parent well restraint into a model that is predictive and accurate for the development of your pad design.

"Let's take the example of a DSU which a company, Turing Assets, wants to design. They plan to drill wells. They also have wells that are offset because they’re parent wells. When they’re thinking about putting in the child wells, they want to be careful that they don’t put them too close to the parents because it’s going to impact the performance of these new wells.

“One of the biggest questions is how far do you space the child wells, so you don’t interfere with the portion of the rock that’s already been drained by the parent wells? We don’t want to frac into the offset drainage because it’s unproductive rock.

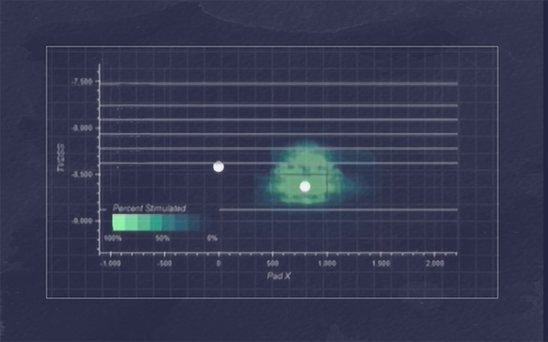

“The way that we handle this at Petro.ai, is before we get to the design prediction, we’ll do a Child Degradation study. This process takes one parent well and one child well. We’ll take this child well and place it at different spacings away from the parent.

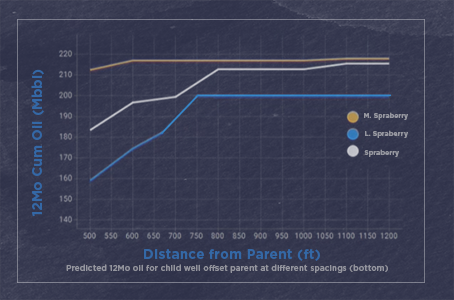

“In this case we start at 400 feet from the parent and move it in 100-foot increments up to say, 1500 feet away. At every one of those positions, we’ll make a prediction on the child well's performance. We’ll calculate the drainage for the child well and then predict the 12 month Cum oil. From there we can get a sense of what that child well degradation would be at different spacings.

“We’ll also move the wells to different intervals. What the graph above is showing is that at different intervals, such as Middle Spraberry, Lower Spraberry and Spraberry, we’ll put the well at a certain interval from the parent and make predictions. We’ll move to another interval location away from the parent and make predictions. We keep testing different intervals and different spacings.Then when we plot the predictions, we can start to see where that degradation no longer exists.

“For a child well in the LS or S, the child well should be at least 700 feet away from the parent, otherwise the performance will be greatly affected. For the S being further away vertically, there’s really no child well degradation from a parent in the S. With the MS, they could stack the well right on top if they wanted to or move it further away without any affect.

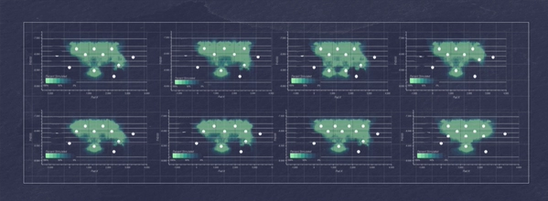

“We run this for every parent well. We do a child well offset analysis for every parent well. Then when we make the final predictions, we’ll include all the offset parents and come up with other designs.

“Below is a gun barrel summary of all the designs we can consider. By running all these different scenarios, we can see the effects that the parents have on the child.

“We’ve found this process to be a fast analysis of the many scenarios that are possible in the vertical and horizontal distances. The conclusions are rapidly analyzed and have a >90% accuracy compared to the 60% accuracy with averaging distances from previously drilled wells. The dependability of this iterative process has had consistent results with our clients. The reports Petro.ai generates are an easy addition to a company’s difficult spacing issues in shale.”