We are active contributors to the technical community in AI, data science, reservoir, and geomechanics.

Quantifying Spacing Degradation in Northern Delaware Basin Using Machine Learning and Subsurface Properties

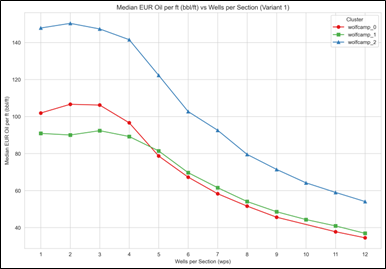

This paper presents an automated modeling system that predicts well performance in unconventional oil development while accounting for geological and geomechanical property variations in the Delaware Basin, particularly in Lea and Eddy Counties. The approach addresses the challenge of quantifying spacing degradation effects within heterogeneous reservoirs where traditional analysis methods often reveal noisy relationships between well spacing and performance. The methodology integrates diverse datasets, including well logs, directional surveys, and production data, to enable data-driven analysis that minimizes interpretation biases. A multi-step process was implemented: first creating interpolated geologic property grids, then developing a spatial clustering framework that identified three distinct geological regimes within the Wolfcamp formation. For each cluster, breakpoint analysis quantified the critical distances at which well interference significantly impacts production. The research culminated in a spacing-aware machine learning model that achieved 78.5% accuracy in predicting normalized production outcomes. This model enabled sensitivity testing across varying well densities (1-12 wells per section) in different geological settings. Results demonstrated that production degradation patterns vary significantly between clusters, with minimal interference effects at up to 4 wells per section across all clusters, and accelerating non-linear degradation at higher densities. The approach provides engineers with quantitative tools to optimize well spacing decisions based on location-specific geological characteristics rather than basin-wide generalizations.

A Machine Learning Approach to Basin Scale Inventory Forecasting and Development Planning that Accounts for Complex Well Interactions

Creating accurate forecasts for inventory locations is challenging due to both the large number of potential locations and the many variables impacting well performance. Future wells are typically assigned a type curve and adjusted using a risk factor to account for well specific unknowns. This approach results in high uncertainty in the expected performance and economic value of future locations. Evaluating the impact of spacing changes or sequencing is time consuming. The system outlined here is a fully automated machine learning (ML) system extending from raw data ingestion to feature generation, model evaluation, and model inference. The ML system is applied here specifically to the creation of a basin model and then predicting well production on inventory locations. The modeling pipeline automates many of the steps needed for predicting well performance, enabling rapid experimentation on the assumptions built into inventory planning. The result is a workflow for teams to explore an enormous number of realizations of various training data and feature sets in hours instead of months. With these tools, engineers can create accurate forecasts for future wells to better inform development planning. The unique time series predictions allow asset teams to move beyond general trends and quantify design changes in terms of NPV. This results in actionable decision insights that can be applied to asset development.

Optimizing Shale Infill Development with AI: Child Well Meta Models

The optimization of infill well placement within drilling spacing units (DSUs) containing parent wells is hindered by the large degree of uncertainty around child well performance. Infill child wells have been observed with up to a 40% degradation from their unbounded parents in the Midland Basin. We present an AI enabled workflow to predict infill well performance and determine optimal child placement and design.

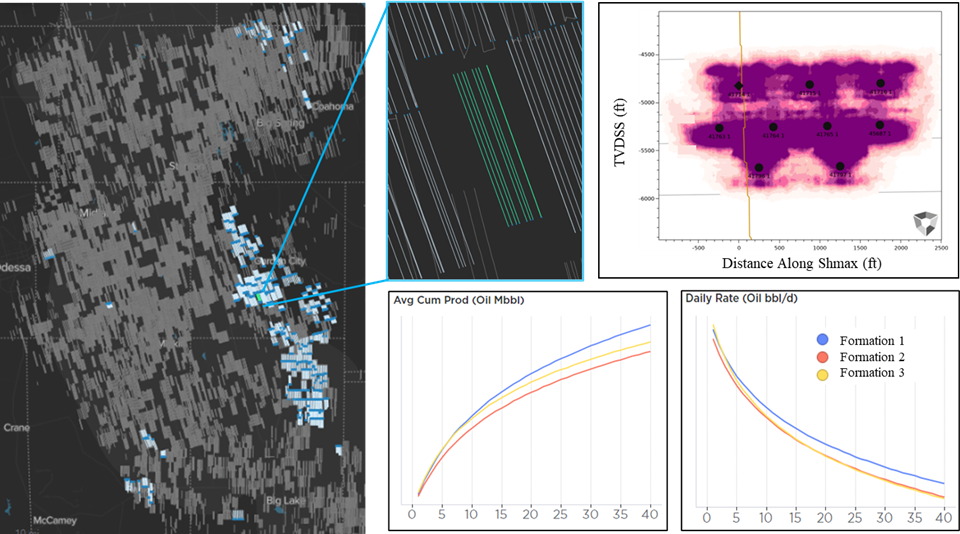

!New Methodology Merging Seismic, Geologic, and Engineering Data to Predict Completion Performance

Previous work in hydraulic fracture performance identifies rock quality and completion quality as key drivers of good production; however, quantifying rock quality in a systematic method along the wellbore is a difficult task. Novel methodologies are developed for calculating rock-quality measurements along the wellbore using seismic data calibrated to geologic information encompassing petrophysical and geomechanical parameters and merging these metrics with stage-level engineering observations. Far-field wellbore seismic attributes correlate with stage completion performance and are promising predictors for improved well design. Further, these integrated attributes may contribute to the fundamental understanding of the hydraulic fracturing process and to the development of more robust and powerful computation models of overall well performance.

Predicting Subsurface Stress using Machine Learning: A Midland Basin Case Study

The state of stress in the subsurface controls how hydraulic fractures will propagate both vertically and horizontally. Accurate models of subsurface stress are needed for optimized well spacing in stacked pay, where lithology can cause large changes in stress between zones. Conventional methods to determine stress require mechanical parameters derived from sonic logs. This approach doesn’t account for stress relaxation that can occur in clay-rich lithologies. Sonic logs may also not be available at the location of interest. The visco-plastic stress relaxation (VSR) theory recently proposed by Singh and Zoback (2022) can produce profiles of Shmin by integrating log and calibration data from the nearby area. This method is applied to a development in the Southern Midland basin. The resulting stress profile was used to optimize spacing for a new pad development.

Variations of the Least Principal Stress with Depth and Resultant Frac Fingerprints

In a recent paper, Petro.ai presented observational data and modeling results which support the hypothesis that the degree of vertical to horizontal hydraulic fracture propagation during multi-stage hydraulic fracturing is largely controlled by variations of the least principal stress with depth. Using two different types of analysis approaches, we investigate complex patterns of vertical and horizontal hydraulic fracture growth from the Midland Basin. In each case, we show that pattern of hydraulic fracture propagation (and resultant drainage volumes) are largely governed by the detailed variation of the magnitude of the least horizontal stress with depth and exact position of a given stage. In gun barrel view, this complex pattern we refer to as a frac fingerprint for convenience. The frac fingerprint depends on the exact vertical position of a frac stage with respect to the variations of the least principal stress in the layers both above and below the stage depth. We briefly discuss the implication of these concepts for choosing optimal well spacings and landing depths and the relationships between hydraulic fracture geometry and drainage volumes.