Q: Can the Petro.ai Drilling Spacing Unit Design Service take asymmetry into account?

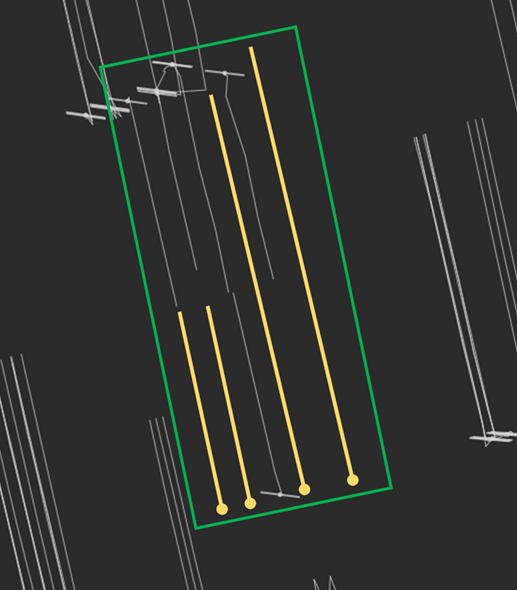

A: “Asymmetry comes up frequently with our clients,” Dr. Brendon Hall, VP of Geoscience at Petro.ai shares in a recent conversation about new value adds to the Drilling Spacing Unit (DSU) Design Service. "There are several types of asymmetries on a DSU. A first might be when you drill a pad there are some wells on the inside or interior of a pad and there are wells on the outside. There’s an asymmetry there. The interior wells have a left and a right side, their boundary conditions are the same. But the exterior wells are asymmetric in that respect; they’re unbounded on one side and bounded on the other side. Petro.ai DSU Design Service handles that case through the mechanism of the frac fingerprint.

“Those wells on the interior have to share their drainage areas with another well on both sides, whereas the wells on the outside don’t have to share that computed drainage area. That’s going to be naturally reflected in the way we compute the drainage area. That falls out naturally with the frac fingerprint.

“Another asymmetry happens when wells aren’t bounded along their entire laterals. You might have one portion of a well that’s bounded and another portion that’s unbounded. Many of our clients are designing between these irregular boundaries. A portion of the well is bounded by an existing well and another portion has no boundaries on one side at all. That’s important to take into account. Again, the frac fingerprint computes these drainage irregularities.

“Another form of asymmetry is accounting for changes along the lateral of the well. Humans influencing the reasonably constant earth properties is an important form of asymmetry. If we drill wells around the wells we’re looking at and we pull out a lot of fluids, we can change the state of the subsurface and the properties there.

“Most notably the pore pressure goes down. The pore pressure is a big component in computing stress. That will change the stress state around that well which can lead to an asymmetry. If a well is drilled in one spot and it’s bounded on one side by a parent and we’ve sucked a lot of the fluids out of the pores of those rocks, then the stress state will go down.

“In another scenario, you can have a well that has a high stress on one side and a low stress on the other. If you’re creating a hydraulic fracture there, we know that these fracs respond to stress and they’ll preferentially want to go over to the area with lower stress. That can cause an asymmetry in that frac diagram. It would grow more towards the area where this parent well has a lot of depletion.”

“To handle that in the frac fingerprint,” Kyle LaMotta explains, “we have applied models to learn that relationship. We’ve done this for many of our clients and the way we account for it is with some calculated features that take specific parameters into account.

“We’ve created models that will learn from the relationship created by those parameters and then apply corrections to the child wells. It’s not doing it from a volumetric standpoint which is what the frac fingerprint does, it’s calculating a factor that we can then apply to the predictions. This is a way to account for a correction to that calculated drainage without actually changing the shape of it.